Basic Approach

The Olympus Group is implementing a variety of environmental activities while assessing the environmental impact of its business activities with precision and with awareness of the scale of the impact on and risk to the environment. Also, following the diversification in our suppliers and with an awareness of climate change as a major environmental issue impacting our business activities, we continue to implement measures to assess information on energy conservation and regulations on reducing CO2 emissions and responding to sudden flooding damage. At the same time, we actively develop and market environmentally conscious products that contribute to resolving issues with climate change and water risk and products designed to resolve environmental issues

Initiatives

Material Balance(FY2022)

| Resource and Energy Input |

Business Activities |

Discharge of Environmentally Harmful Substances |

| Energy (Total) |

328,906 MWh (7%)★ |

| Electric power |

127,967MWh (7%)★ |

Gasoline |

5,120kL (33%)★ |

| City gas |

5,836 thousand m3 (27%)★ |

Hot water |

2,288GJ (8%)★ |

| LPG |

1,475t (-5%)★ |

District heat |

2,280MWh (17%)★ |

| LNG |

834t (4%)★ |

Green electricity |

29,180MWh (53%)★ |

| Heavy fuel oil |

201kL (-2%)★ |

Solar power [internal] |

526MWh (2%)★ |

| Kerosene |

83kL (40%)★ |

Solar heat [internal] |

455GJ (-6%)★ |

| Diesel fuel |

867kL (-3%)★ |

Chemical Substances [PRTR Substances Handled]

* Production sites in Japan only |

41t (1%) |

| Water (Total) |

961 thousand m3 (-9%)★ |

| Piped water |

315 thousand m3 (-18%)★ |

| Ground water |

646 thousand m3 (-4%)★ |

Raw Materials and Sub-Materials * Production sites in Japan only

| Metal: |

Steel, alminium, brass |

| Plastics: |

Optical plastics, ABS, PC, polyethylene, polypropylene |

Office Supplies

Transporation Fuel

| Transportation: |

Gasoline, diesel fuel, etc. |

| Packaging Materials (Total) |

1,016t (-2%) |

| Cardboard |

616t (0.5%) |

| Paper |

185t (-15%) |

| Plastic |

184t (2%) |

| Metal |

0t (0%) |

| Glass |

0t (0%) |

| Others |

31t (7%) |

|

Development and Manufacturing

(Research)Development

Production

Sales and Logistics

Logistics

Sales

Repair and Service

|

| Greenhouse Gases (Total) |

90,119t-CO2e (-3%)★ |

| CO2 generated from energy |

90,118t-CO2e (-3%)★ |

| CO2 not generated from energy |

1t-CO2e (-83%)★ |

Substances Emitted

Chemical Substances (PRTR substances emitted and transferred)

* Production sites in Japan only |

15t (-5%) |

| Discharge to Water Systems (Total) |

961 thousand m3 (-9%) |

| Water discharged (public waters) |

524 thousand m3 (-4%) |

| Water discharged (sewage) |

437 thousand m3 (-14%) |

| BOD(t) |

2t (19%) |

| Discharge (Total) |

5,362t (-8%)★ |

| Amount recycled |

4,575t (-5%)★ |

| Other waste |

787t (-21%)★ |

| Landfill |

99t (57%)★ |

| Hazardous waste |

265t (-8%)★ |

| CO2 Emissions during Transportation (Total) |

41,177t-CO2e (18%) |

| Product Shipments |

| Main products (Total) |

2,173t (-4%) |

| Medical Business (Endoscopes) |

1,233t (-1%) |

| Scientific Solutions Business (Microscopes) |

940t (19%) |

|

|

★ Indexes certified by the Assurance Statement. Percentage change from previous year in brackets |

Energy/Atmospheric Release

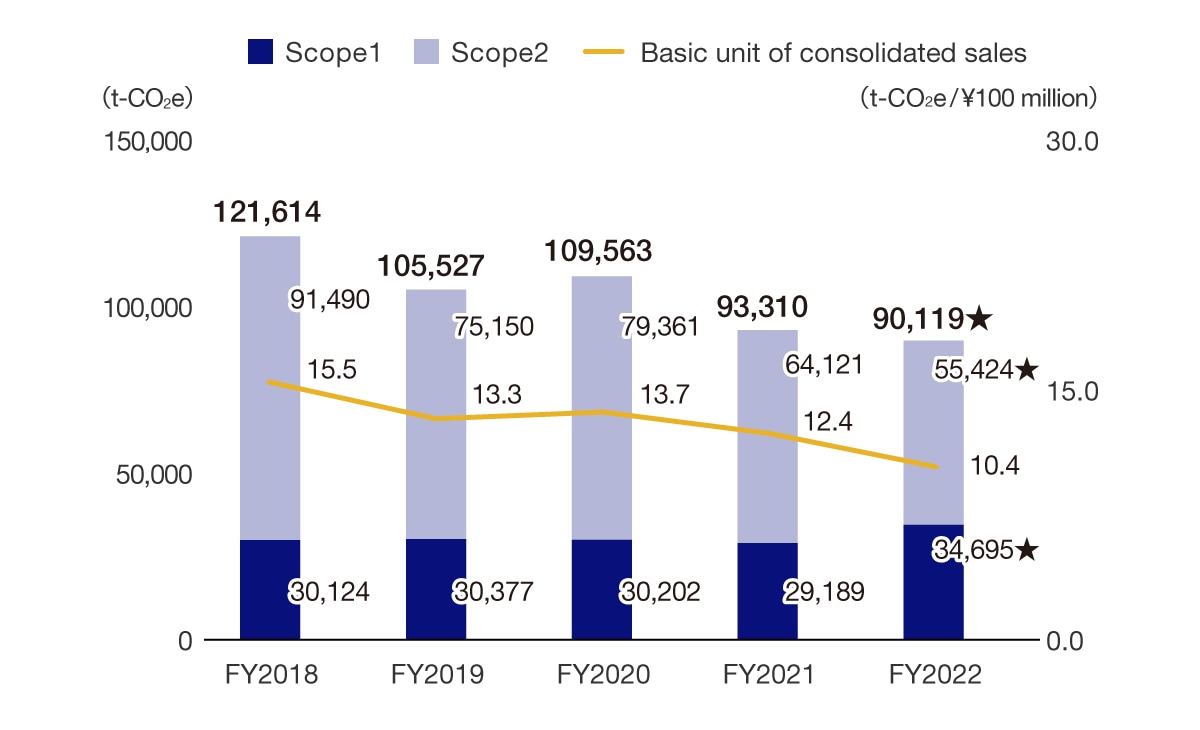

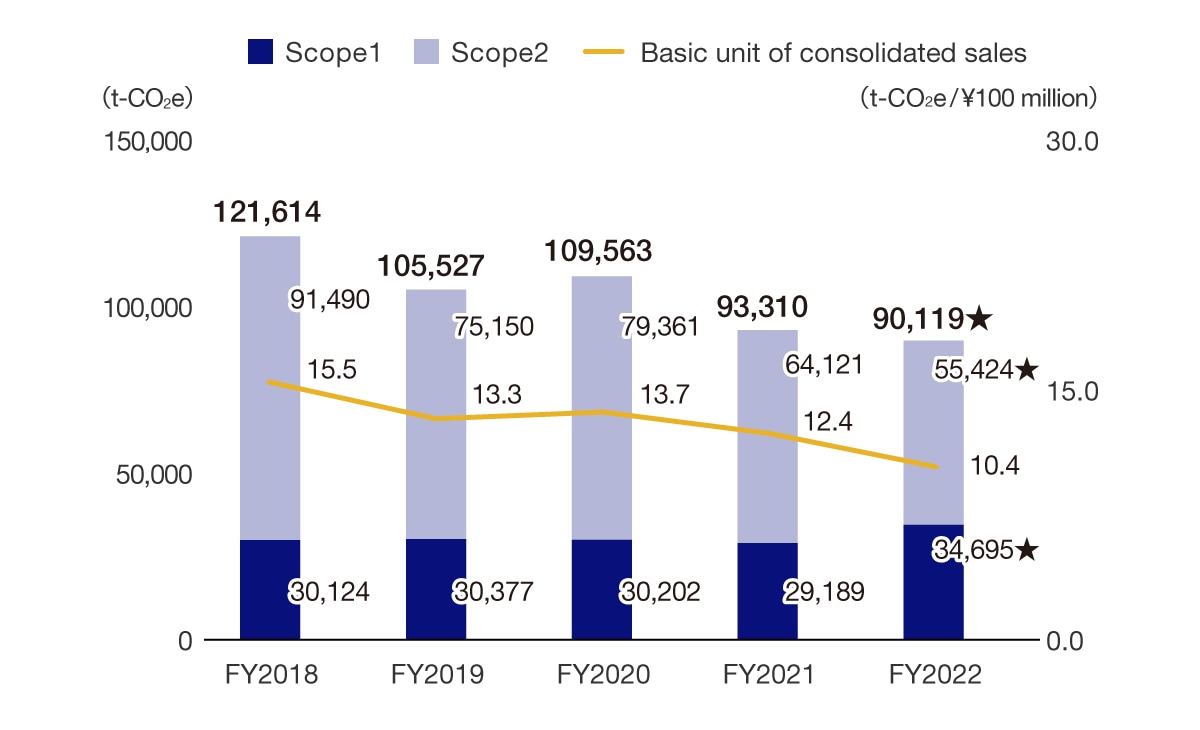

Internal (Scope 1, 2) Results

| FY2022 Targets |

FY2022 Results |

Main Measures |

FY2023 Targets |

|

CO2 emissions: reduced by 21% compared to FY2018

Renewable energy rate: more than previous year

|

CO2 emissions: reduced by 25.9% compared to FY2018

Renewable energy rate: 18.9%

|

- Ongoing implementation of manufacturing improvement activities

- Introduction of energy saving equipment

- Ongoing implementation of energy-saving activities on a daily basis, including switching off lights and adjusting air-conditioning temperatures

- Introduction of environmentally conscious cars

- Effective use of renewable energy

|

CO2 emissions: net zero (FY2031)

Renewable energy rate: 100% (FY2031)

|

In May 2021, the Olympus Group set a carbon neutrality goal of net zero CO2 emissions from group facilities by 2030. While continuing to promote manufacturing improvement activities and energy-saving measures, we are working to reduce CO2 emissions by promoting the introduction of renewable energy at our operation sites. In addition, at sites where energy use is high, we are promoting initiatives by appointing our own experts and establishing a system to promote energy conservation.

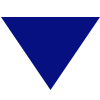

In FY2022, continual improvements in manufacturing, energy-saving measures, updates company cars to environmentally conscious cars and the use of renewable energy were considered at its sites around the world. At our Hachioji Facility, boiler efficiency was improved by installing thermal jackets on the boiler piping to reduce thermal energy loss and improve boiler efficiency, and Aomori Olympus has worked to reduce energy waste by replacing compressors with high-efficiency equipment and installing air flow meters to identify air leaks and implement countermeasures. KeyMed (Medical & Industrial Equipment) Ltd. in Europe switched some of its company vehicles used for sales activities to electric vehicles. At Olympus Surgical Technologies America (Gyrus ACMI, Inc.), starting in 2021, 30% of the electricity used at the Redmond site, 100% at the Bartlett site, and 20% at the newly opened Westborough site switched to renewable energy sources. In April 2022, we converted 100% of the electricity used at our major development and manufacturing sites in Japan (10 sites) to electricity derived from renewable energy sources.

For wider use of renewable energy, studies are focusing on dissemination, economic feasibility and other factors in each country.

The renewable energy use rate vis-á-vis the total electric power consumption has risen to 18.9% (compared to 12.2% in the previous year).

Olympus will continue to build environmentally friendly buildings when constructing or reconstructing business sites, and Olympus Europa SE & Co. KG and Olympus Winter & Ibe GmbH have acquired German Sustainable Building Council Gold Certification (DGNB certification*1) for their newly constructed buildings.

Olympus Corporation participates in the Carbon Neutral LNG Buyers Alliance as a part of new initiatives to reduce CO2 emissions, and has started to introduce carbon neutral LNG*2 to the Hachioji Facility.

*1 DGNB certification: Environmental certification for architectural structures issued by the German Sustainable Building Council to reduce the environmental impact of structures.

Certification is given after assessment of the environmental performance of the building and confirmation that the structure satisfies certain criteria.

*2 Carbon neutral LNG: A type of LNG that offsets greenhouse gases generated in the processes from the extraction to the burning of natural gas with carbon credits created by environmental conservation projects.

Carbon Neutral LNG (Only in Japanese)

Gold in DGNB certification

New office building: Olympus Europa SE & Co. KG

Olympus Winter & Ibe GmbH

Boiler piping jacket installation

Green Energy Certificates

Olympus Surgical Technologies America (Gyrus ACMI, Inc.) (U.S.A.)

Olympus Europa SE & Co. KG

(Germany)

KeyMed (Medical & Industrial Equipment) Ltd. (U.K.)

Olympus Surgical Technologies America: Redmond (Gyrus ACMI, Inc.) (U.S.A.)

Logo for the Carbon Neutral LNG

CO2 emissions/intensity (Scope 1, 2)

External (Scope 3 [Category 4 Upstream transportation and distribution]) Results

| FY2022 Results |

Main Measures |

| CO2 emissions: reduced by: 18.9% (compared to FY2018) |

- Enhanced loading efficiency by improving packaging size and strength

- Reduced transportation weights by improving packing and packaging methods

- Shortened lead times and transportation distances by improving logistics routes

|

The Olympus Group is engaged in reducing logistics-related CO2 emissions at each of its sites. We continue with improvements, including optimizing the loading efficiency of transportation containers by products type and shape, consolidating logistics sites for transportation efficiency and direct shipping by reviewing logistics routes. In FY2021, Olympus Logitecs in Japan switched some of the air and charter flights used for domestic transport to JITBOX charter flights*1 to reduce CO2 emissions.

*1 JITBOX Charter Service: A service that allows customers to request pallets of roll box cargo and combine them with other companies' cargo for transportation at a high loading rate.

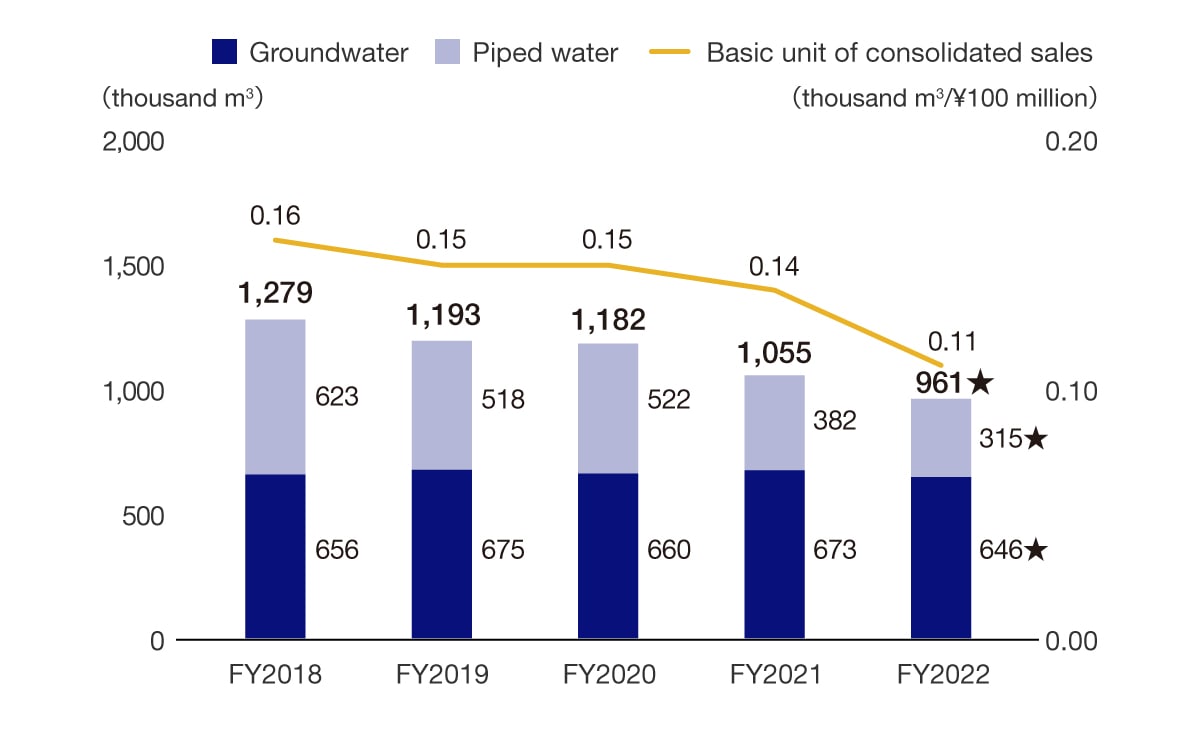

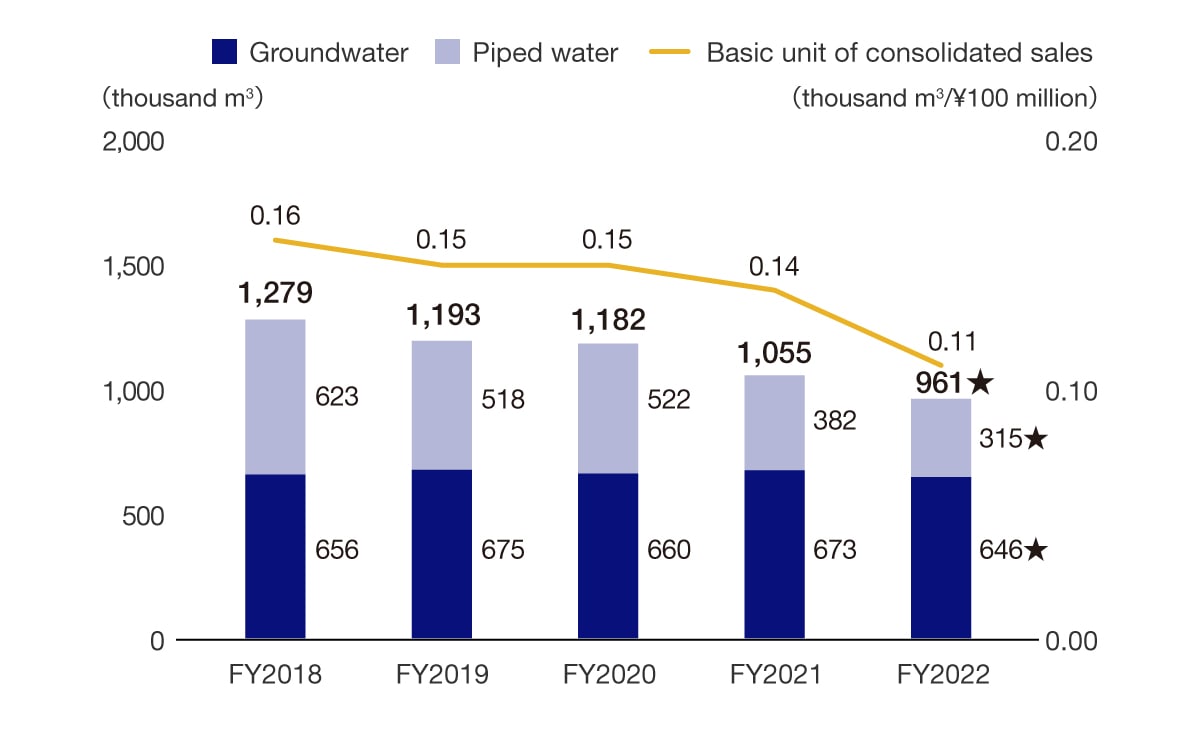

Water/Emission

Water Use/Wastewater Results

| FY2022 Targets |

FY2022 Results |

Main Measures |

FY2023 Targets |

Water use intensity: improve by 7% compared to FY2018 |

Water use intensity: improved by 32.0% compared to FY2018 |

- Improvements in water use processes

- Implementation of measures against water leakage during equipment inspections

- Implementation of secondary use of water

|

Water use intensity: improve by 1% compared to FY2022

* Our initial target of a 23% improvement has already been achieved, so activities for a 1% improvement over the previous year will be conducted. |

The Olympus Group uses water mainly in production processes, such as for cleaning components and cooling, as well as in its dining halls. We implement thorough wastewater control by adopting stricter standards than the legal requirements in each region, and we continue to reduce water consumption and wastewater emissions by setting targets in those sites that have high water consumption. We are also acting to conserve water resources under collaborations with local communities at each site.

In FY2022, we reassessed the water risks at each of our sites using water risk assessment tools (e.g. Water Risk Filter, Aqueduct), hazard maps, and their water usage. In Japan, our Nagano Facility makes effective use of waste water from the purification of deionized water by collecting it for secondary use in the manufacturing process, the Shirakawa Facility has reduced water consumption by shortening the time required for washing with hot running water after surface treatment in the manufacturing process; and Aizu Olympus has reduced water consumption in the painting process by changing the cleaning process from small lot processing to batch processing and introducing water-saving shower washing machines in a separate process. KeyMed (Medical & Industrial Equipment) Ltd. in Europe purifies and reuses water from the painting process. At our Nagano Facility, with the consent of the local fishery cooperative, wastewater is continuously monitored, and regular inspections of water treatment facilities are carried out to ensure strict water management so as to minimize the impact on the ecosystem. The Nagano Facility also helps maintain the local forest that serves as a water source for the area under a Forest Fostering Agreement concluded with the Monzen Forest Association and Tatsuno Town in Nagano Prefecture. Olympus Surgical Technologies America (formerly Gyrus ACMI, Inc.) in the U.S. received a Gold Award*1 in recognition of long-time efforts to maintain compliance with the industrial wastewater discharge permit requirements set by King County, Washington.

*1 Presented to companies that have met the standard of the Gold Award set in the program of industrial wastewater discharge permit requirements by King County, Washington.

Commitment-to-Compliance Award

Water Use

Water Use

ESG Data

Wastewater Results

ESG Data

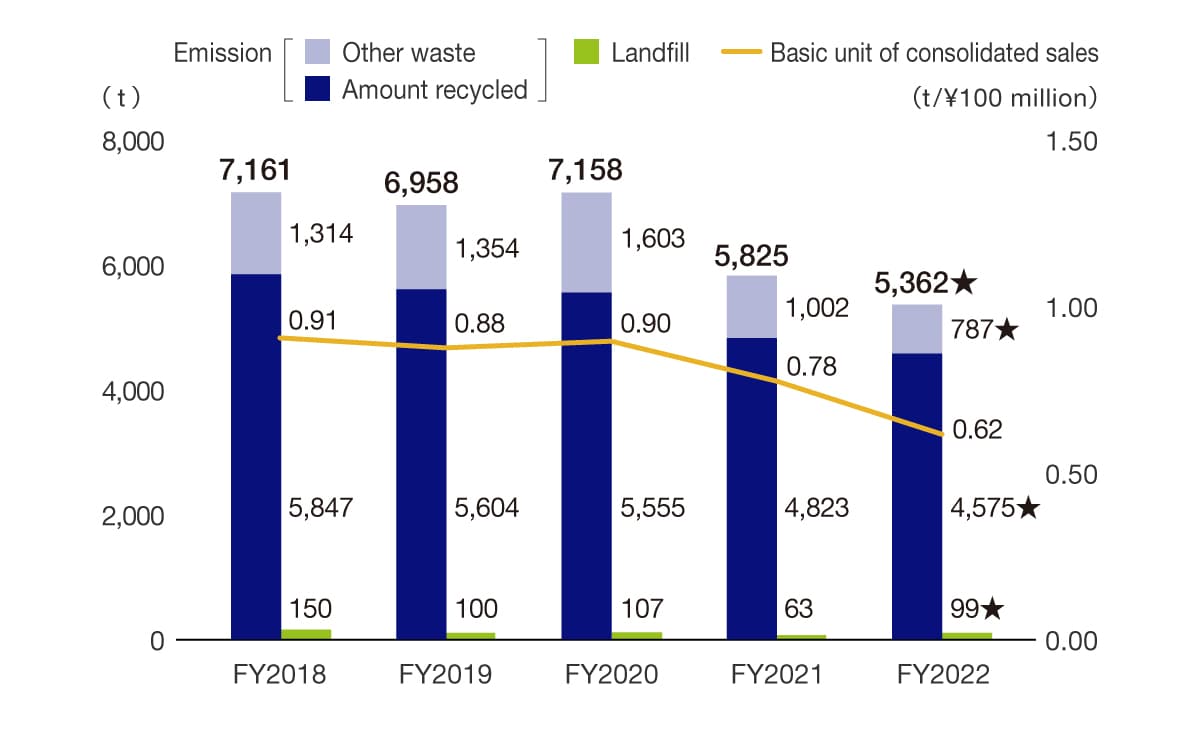

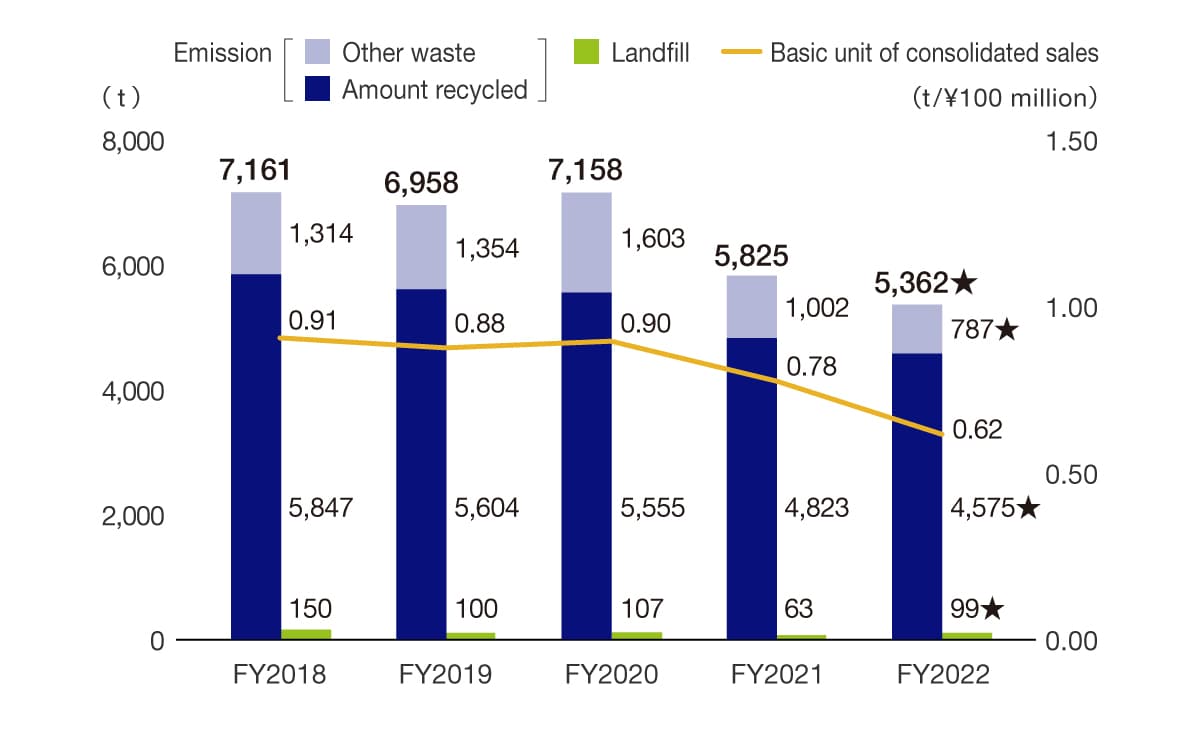

Emission Results

| FY2022 Targets |

FY2022 Results |

Main Measures |

FY2023 Targets |

Emission intensity : improve by 7% compared to FY2018 |

Emission intensity : improved by 32.2% compared to FY2018 |

- Reduction of process defects

- Promotion of recycling by thorough separation

- Promotion of reusing package materials

- Extracting valuable materials from wastes

|

Emission intensity: improve by 1% compared to FY2022

* Our initial target of a 23% improvement has already been achieved, so activities for a 1% improvement over the previous year will be conducted. |

The Olympus Group is working continually on reducing losses in manufacturing processes by making improvements to them and efficient use of resources, including thorough waste separation to reduce waste discharge, extract valuable materials and promote recycling.

In FY2022, paper usage was significantly reduced at our development sites and offices due to digitalization associated with increased remote working progressed by our Work Style Reform. In Japan, Olympus Logitex is reducing the use of corrugated cardboard by making products without packaging, reducing waste by using returnable containers and expanding the reuse of cushioning materials, and the Olympus Medical Systems’ Hinode Plant is promoting the effective use of resources by converting production equipment into valuable resources when they are to be disposed of. In Asia, Olympus Vietnam Co., Ltd. generated a large amount of unneeded equipment due to the building division work associated with the sale of its imaging business in December 2021, but recycling was promoted to reduce the environmental impact. Olympus Surgical Technologies America Inc. provides an intra-company awareness raising program to help employees increase the recycling rate, and at the Bartlett sites, PPE waste (personal protective equipment used at medical facilities, etc.), which had been sent to landfills, is now being recycled by purchasing special boxes from a vendor and outsourcing the processing to them. In addition, the Bartlett site signed up to the "Tennessee Recycling Coalition*1" to explore new ways of recycling, develop and expand the reuse and recycling market, and continue to study ways to further reduce waste.

Our hazardous waste emissions have been reduced 7.5% compared to FY2021 by reinforcing waste management and replacing certain chemical substances with safer ones.

*1 Tennessee Recycling Coalition: A non-profit organization dedicated to promoting recycling and sustainable materials management practices in Tennessee, U.S.

Recycling of PPE waste (personal protective equipment at medical sites, etc.)

Emission/Landfill

ESG Data

Hazardous waste discharged

ESG Data

Emission/Landfill

Chemical Substance Safety and Control

| FY2022 Results |

Main Measures |

Emissions and Movements of PRTR Class 1-Designated

Chemical Substances: Reduced by 17.5%

(compared to FY2018) |

- Substitution of PRTR-designated chemicals with other substances through material developments

- Reduced usage of PRTR-designated chemical substances

|

The Olympus Group is striving for appropriate management and emissions reduction of chemical substances subject to the PRTR regulations and volatile organic compounds (VOC) in order to minimize the impact on people and the environment. In FY2022, we continuously reduced the use of organic solvents through improvements to the cleaning process of components, etc., at each manufacturing site.

Emissions and Movements of PRTR Class 1-Designated Chemical Substances

|

FY2018 |

FY2019 |

FY2020 |

FY2021 |

FY2022 |

| Emissions and Movements of PRTR Class 1-Designated Chemical Substances |

17.7 |

18.8 |

19.3 |

15.4 |

14.6 |

* Scope: Manufacturing and development sites in Japan

Volatile Organic Compound (VOC) Emissions

|

FY2018 |

FY2019 |

FY2020 |

FY2021 |

FY2022 |

| Volatile Organic Compound (VOC) Emissions (t) |

62.3 |

81.9 |

83.9 |

57.8 |

56.7 |

※ 対象範囲:日本の全製造・開発拠点

Product Life Cycle Assessments

The Olympus Group works to develop products and production technologies that show consideration for safety and for the environment. Having in FY2004 established its Eco-Products Administration Rules, a voluntary standard relating to the environmental considerations of our products, we continue to certify our products as Olympus Eco-Products.

In addition, a life cycle assessment (LCA) is performed at each stage of a product's life cycle to assess its impact on the environment at the product development stage and from procurement through manufacture, distribution, use and final disposal. Clarifying the environmentally conscious aspects that differ for each product, we have set them as items for the environmental consideration standard.

We are working to reduce the use of containers and packaging materials, and promoting effective use of resources.

Examples of Environmentally Conscious Products

The Olympus Group works to show consideration for the environment through the products in each of its business fields.

Medical Business

Video Gastroscope GIF-XZ1200

- Video Gastroscopes GIF-XZ1200

< Main Product Features >

- Maximum 125 times magnification and superior image quality using a high-sensitivity CMOS image sensor.

- High-speed sequential color imaging delivers an image with higher resolution and minimum chromatic aberration.

- New ErgoGrip improves usability for operators.

< Environmentally Conscious Aspects >

- Reduction in product weight.

Products that Contribute to Solving Environmental Issues

Utilized even at the forefront of automobile and aircraft development with the aim of improving the efficient use of energy and the recycling facilities, Olympus products contribute to solving environmental issues.